30. May 2025 By Dr. Patrick Kübler and Dr. Uwe Pohlmann

Production digitalisation with AI & Metaverse?

Why well-thought-out IT-OT integration determines success or failure

Technologies such as artificial intelligence (AI) and the industrial metaverse promise a profound transformation of industrial production systems. But while these concepts offer the potential for new efficiency gains, their implementation in practice often falls short of expectations. Since the term ‘Industry 4.0’ was coined in 2011, many expectations have been raised, but 13 years later, it is clear, especially in industrial manufacturing, that the key to success lies not only in technology, but in the structured integration of IT and OT systems that creates a consistent data base.

In AI and metaverse projects in particular, many companies find that they reach a point where they cannot progress because data is available in different formats, systems or plants. This lack of a data base slows down scaling, so that promising pilot projects are nipped in the bud.

From pilot projects to production-wide scaling – a rocky road

Numerous companies have now launched initial pilot projects with AI or metaverse components – for process optimisation or digital factory planning, for example. These use cases demonstrate the potential of digital technologies. Nevertheless, comprehensive scaling to entire plants or production networks is still largely absent.

One key reason for this is that production data is often distributed, inconsistently structured and difficult to access. In addition, many companies have legacy systems that were hardly planned from scratch.

The system landscape is characterised by heterogeneous hardware, different control systems and legacy software architectures. In many companies, each plant resembles its own technological cosmos – with individual applications, interfaces and data models.

Three key challenges in the production environment

These structural conditions lead to specific problems in the following areas:

1. Planning of factories and manufacturing systems

Planning new or modified factories requires the integration of numerous trades. If existing plant structures are incorporated, this places high demands on data quality and consistency. Without uniform data models, the use of simulation-based planning methods becomes unnecessarily complex and time-consuming. In Europe in particular, existing plants are rarely built from scratch, which means that data from legacy systems has to be laboriously merged.

2. Production planning and control

In companies without end-to-end system integration, planning and control are often based on different data sets. Media breaks and manual validation steps lead to longer throughput times and limited responsiveness in the event of disruptions. Without company-wide harmonisation (e.g. of master data), each location becomes its own ‘island’.

3. Data-driven optimisation of existing processes

Although numerous optimisation measures have been implemented in the past using lean approaches, data-driven improvements are often lacking. One reason for this is that individual data analyses are time-consuming, do not deliver the expected benefits or are difficult to transfer to other machines or plants, resulting in a so-called ‘use case vicious circle’. When it comes to topics such as OEE optimisation or predictive maintenance, companies often fail due to a lack of standards for data recording and evaluation.

IT-OT integration as a strategic investment

Some companies have broken this cycle by making a conscious decision to invest in their IT-OT architecture. Although this decision initially involves some effort and does not bring any savings in the short term, it lays the foundation for long-term scalability.

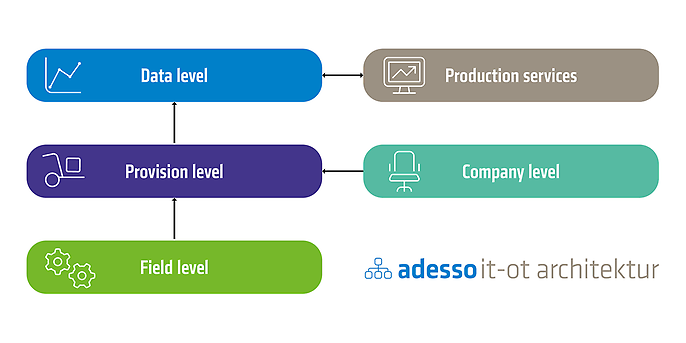

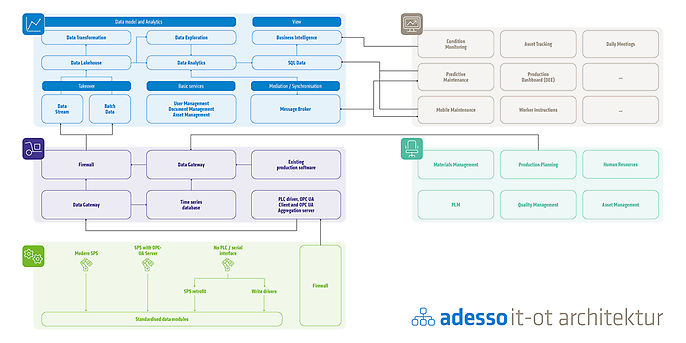

The key lies in centralised platform solutions that can be provided as a self-service offering for different plants and production areas. These platforms enable data to be consistently collected, processed and made available for cross-functional applications – from simple key figure analysis to AI-based forecasting models. It is important to clearly define roles between the field level (machines/PLCs), provisioning (data integration with business applications) and a central data level on which analytics and applications are based.

Companies are increasingly relying on ‘IT-OT convergence’ to ensure that data-based projects do not end up as isolated island solutions. This interaction enables data modules that have been defined once to be used for many use cases (such as predictive maintenance or AI-supported quality testing).

Status check

Where does your production stand in terms of digitalisation?

Are you wondering how to use production data intelligently, successfully bring IT and OT together, and deploy digital technologies such as AI or the Industrial Metaverse in a scalable way?

We show you concrete approaches for turning pilot projects into real productivity gains.

Contact us now with no obligation and receive advice from our experts

Architecture as an enabler: How to make IT-OT integration work

A proven IT-OT architecture comprises several clearly defined layers that build on each other:

Levels of the adesso IT-OT architecture

Field level

This is where data is generated directly at the machines and processed at the control level (e.g. PLC). The aim is to compensate for heterogeneity through standardisation – for example, by defining uniform data blocks. This makes it easier to merge production information from different plants at a later stage.

Provision level

At this point, data from the field level is linked to other company data (including ERP systems) and made available in a uniform format. This forms the bridge between OT and IT. Typically, interfaces are defined here that can be used throughout the entire company, rather than individual ‘patch solutions’ in each plant.

Data level

The aggregated data is stored centrally and made available for analysis. This layer should be structured consistently across the company to enable scalable data processing. Especially in AI applications, it is crucial that data is standardised and complete in order to train reliable models.

Application layer

Applications based on the analysed data are made available here – for example, dashboards for plant availability (OEE) or intelligent assistance systems. The plants use the solutions as needed – individual adjustments remain possible if they make economic sense. This central application layer allows new use cases to be rolled out more quickly because there is no need to start a ‘data collection marathon’ every time.

Implementation options: cloud, hybrid or on-premise

The specific technical implementation of such an architecture can vary:

- Cloud-based: Solutions based on Microsoft Azure or AWS offer high scalability and flexibility – especially for internationally active companies.

- On-premise with open source components: For organisations with special security requirements or compliance regulations, operation in their own data centre is a good option.

- Hybrid models: Sensitive data remains on-premise, while computationally intensive analyses are performed in the cloud.

The decisive factor is not the technology itself, but its integration into a clear overall architecture. Hybrid models are also possible, in which sensitive data remains on-premise while computationally intensive analyses are performed in the cloud.

Success factor: collaboration – bringing IT and production together

In addition to technical requirements, organisational cooperation is also of central importance. IT and OT teams traditionally work separately – with different objectives and terminology. For IT-OT convergence to work, it is necessary to form interdisciplinary teams and develop a common understanding. Close communication between subject matter experts (on the shop floor) and data/software specialists is essential, especially in the context of AI or metaverse projects.

Conclusion: Architecture as the foundation for productive digitalisation

The digitalisation of production cannot be achieved simply by introducing AI or other trend technologies. Rather, a stable and well-thought-out IT-OT architecture is the central prerequisite for sustainable efficiency gains. Companies that invest in such a structure today and harmonise their system landscape – i.e. eliminate data silos – are laying a foundation on which new applications can be scaled quickly and economically: technologically, organisationally and economically.

Those who consistently follow this path ensure that pilot projects do not remain isolated solutions, but lead to productive added value throughout the entire production network.

We support you

Are you facing the challenge of integrating AI or the Industrial Metaverse into your production, but encountering data silos, complex system landscapes or missing IT-OT interfaces? We at adesso accompany you from the first workshop to a scalable platform solution.