7. November 2023 By Till Möller

Machine learning on the Smart Product Platform: a predictive maintenance showcase brings future technologies to life

Predictive maintenance for machines and plants is an innovative technique that is currently revolutionising the industry. This advanced technology promises to reduce maintenance, slash unplanned downtime and increase the efficiency of your systems using machine data and (retrofit) sensors from the world of Internet of Things (IoT). Predictive maintenance is based on the analysis of real-time data (time series data) collected from IoT sensors and other sources. This data is processed with the help of advanced algorithms to detect potential problems or signs of wear in machines at an early stage. This means that maintenance work no longer has to be carried out on a strict schedule; instead, it can be done as needed.

In the field of predictive maintenance, we often talk about detecting anomalies in time series. But what does that actually mean? And how does it work? This blog post presents approaches used to analyse time series data and detect anomalies. It also describes ways to successfully integrate the algorithms into a smart product platform, the Smart Product Platform in this particular case.

An brief introduction to time series analysis and anomaly detection

Basically speaking, an anomaly is a data point or pattern in a time series that differs from the data you would typically expect to receive. Anomaly detection deals with the task of identifying these irregularities. But in practice, this task is extremely complicated since different types of anomalies can occur. We will touch on this briefly later on.

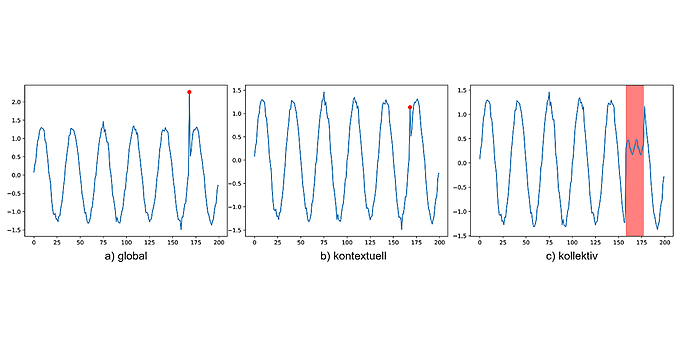

Anomalies in time series can take various forms. Having a deeper understanding of the categories of anomalies helps you better analyse the results generated as part of the anomaly detection process. While individual outliers can occur as anomalies, there are also entire patterns that can be recognised as anomalies. Within this spectrum, individual anomalies can be divided into two main categories: global and contextual anomalies.

Global anomalies are data points that differ significantly from all other data points in the time series. By contrast, contextual anomalies are outliers that deviate locally from a particular pattern.

Beyond that, there are also collective anomalies, which refer to a grouping of data points that represent a deviation over a specific period of time.

The different types of anomalies are presented in Figure 1. A red dot represents a single anomaly, while a red shaded area indicates a time window as an anomaly.

Figure 1: Examples of types of anomalies; source: Revisiting Time Series Outlier Detection: Definitions and Benchmarks, https://openreview.net/pdf?id=r8IvOsnHchr

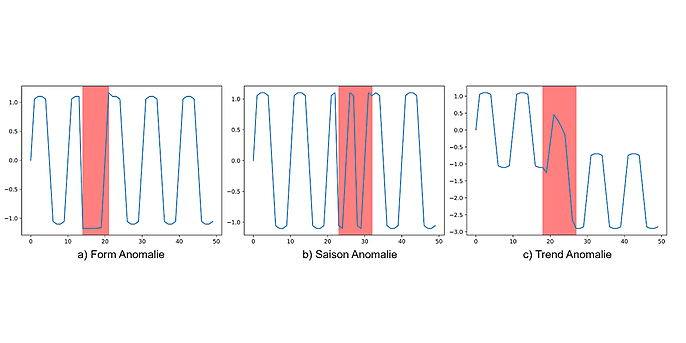

As we previously learned, deviant patterns can also be categorised as anomalies. These differ in terms of shape, seasonality and trend. Shape anomalies occur when partial sequences in the time series have a different general shape than the normal trend. An example of this would be a sinusoidal signal that suddenly changes into a square wave function. In the case of seasonal anomalies, the seasonality changes for a certain subsequence of the time series, for example, a sinusoidal signal could have a higher frequency for a short period of time. Finally, there are trend anomalies, where the shape and seasonality of the time series remain the same, but the time series offset in a subsequence shifts or the slope changes. This leads to a deviation in the mean of the data. Shape, seasonal and trend anomalies are shown in Figure 2, where the red shaded area also represents a time window that is anomalous.

Figure 2: Examples of different types of anomalies in a time window; source: Revisiting Time Series Outlier Detection: Definitions and Benchmarks , https://openreview.net/pdf?id=r8IvOsnHchr

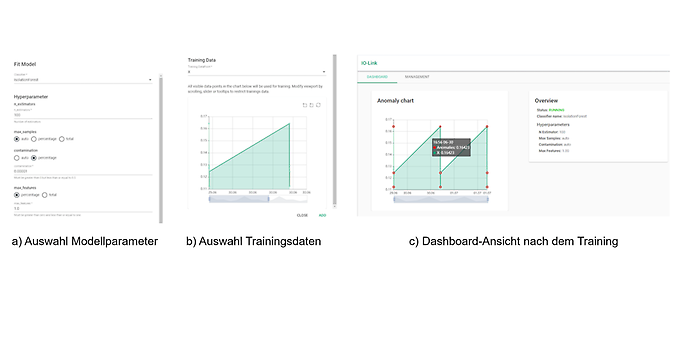

Different types of anomalies happen all the time in customer projects, which is why anomaly detection should be simple and user-friendly. For that reason, an integration that includes a graphical user interface was implemented on our IoT platform.

Integration into the Smart Product Platform

In general, the Smart Product Platform, which is also used as a smart product platform, provides a full range of services that allow you to efficiently implement customised IoT solutions for a wide variety of use cases. The platform can be used both as software-as-a-service (SaaS) and as an on-premise solution. In many cases, the platform is employed to manage assets such as machines, sensors or vehicles, store the data that is generated in the cloud and provide value-added services such as condition monitoring for the service, for example.

Anomaly detection was integrated as a separate microservice that provides machine learning functions. As a result, this module can be easily embedded in customer applications if so desired. A generic web UI is provided to make the service easy to use. The user can train a separate ML model for each asset in this UI. Once this has been done, the model can be activated to monitor incoming data. All information about a created model can be monitored via a separate dashboard. (See attachment for images)

Figure 3: Sections of the WebUI for creating a model (a, b) and the dashboard (c)

If you would like to find out more about the IoT platform and possible ways to use using machine learning, contact us now.

Would you like to learn more about exciting topics from the adesso world? Then take a look at our latest blog posts.

Also interesting: